ASPUR aero2GD gas-tight

Deduster ASPUR aero2GD gas-tight

Modern, high-quality, compact deduster in gas-tight design, with the typical ASPUR design. Smooth surfaces, few protrusions and attachments ensure a "clean" appearance.

Extraction units in gas-tight design are connected to machines via gas-tight piping systems, filled with gas and operated in recirculation mode. All components are equipped with special seals. After assembly, the unit is pressurized and tested for gas leaks.

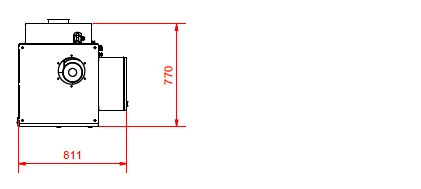

Drive

The unit is driven by EC high-performance blowers. All variants can be used in multi-shift operation. The required air flow rate is continuously adjustable from 0-100% on the display.

Controller

A Rittal control cabinet with Siemens LOGO® modules and display allows manual or automatic adjustment to the desired performance parameters of the unit. This reduces unnecessary wear and tear. The integrated differential pressure sensor enables constant monitoring of the filter conditions. Via the Modbus equipment, all functions of the deduster can also be transferred to a customer's control system and operated from there.

Filter system

The unit is equipped with an integrated H14 filter, which ensures a particle separation of over 99.995%. The integrated star filter is equipped with an integrated electrical filter cleaning system. Due to this design, the units are suitable for extracting even small amounts of process dust. Due to the modular design, additional filter systems can be added on customer request and, under certain circumstances, upgraded at a later date.

Dust container

The unit has a gas-tight discharge flap and endless bag system with dust-free disposal option. After opening the flap, the process material enters the sealed dust bag. This is double-sealed and cut off in the middle before disposal. By retracting the bag, it is available for further filling.

Standard equipment

Product data

Product features |

|---|

| High-quality star filter system with electrical filter cleaning |

| Integrated H14 filter |

| Large access doors (service friendly) |

| EC motors |

| Control cabinet with frequency converter and display (user-friendly) |

| Incl. Modbus TCP control and 24V potential-free contact |

| Sound insulation of the housing for quiet operation |

Order now our deduster gas-tight aero2gd for your workplace

Areas of application |

|---|

| Processes |

| Lasering, welding, cutting |

| Filling, mixing |

| Materials |

| Fume, smoke |

| Dust, fine particles |

Order now our deduster gas-tigth aero2gd for your workbench!

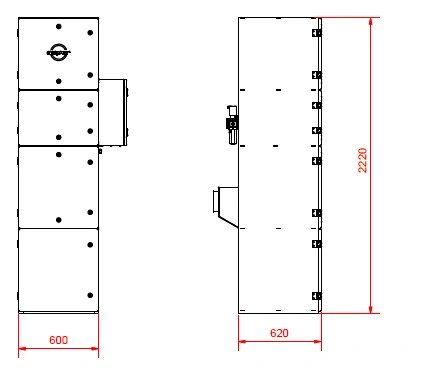

Technical data

| aero2gd EC 1.1 | aero2gd EC 2.2 | aero2gd EC 1.4 | aero2gd EC 2.8 | aero2gd EC 4.0 | |

|---|---|---|---|---|---|

| Item no. | 9120000 | 9120001 | 9120002 | 9120003 | 9120004 |

| Air volume flow | max. 360 m³/h | max. 720 m³/h | max. 940 m³/h | max. 1880 m³/h | max. 2000 m³/h |

| Negative pressure | max. 11000 PA | max. 11000 PA | max. 5000 PA | max. 5000 PA | max. 5000 PA |

| Drive power | 1.1 kW | 2x 1.1 kW | 1.4 kW | 2x 1.4 kW | 4.0 kW |

| Voltage | 230 V | 230 V | 230 V | 230 V | 400 V |

| Sound emission | 62 dB(A) | 64 db(A) | 63 dB(A) | 65 db(A) | 65 dB(A) |

| Weigth | 210 kg | 212 kg | 212 kg | 214 kg | 215 kg |

| Dimensions (l,w,h) | 600x600x2000 mm | 600x600x2000 mm | 600x600x2200 mm | 600x600x2200 mm | 600x600x2200 mm |

| Dimensions¹ (l,w,h) | 800x800x2000 mm | 800x800x2000 mm | 800x800x2200 mm | 800x800x2200 mm | 800x800x2200 mm |

| Intake port² (d) | 50 mm | 70 mm | 100 mm | 150 mm | 150 mm |

| Exhaust port² (d) | 50 mm | 70 mm | 100 mm | 150 mm | 150 mm |

| Endless bag system | ja | ja | ja | ja | ja |

| Powder coating | RAL9016 mat | RAL9016 mat | RAL9016 mat | RAL9016 mat | RAL9016 mat |

| Filter typ | Star filter polyester | Star filter polyester | Star filter polyester | Star filter polyester | Star filter polyester |

| Filter classes | M, H | M, H | M, H | M, H | M, H |

| Filter class H14 | ja | ja | ja | ja | ja |

| Filter surface | 8 m² | 8 m² | 8 m² | 8 m² | 8 m² |

| Filter surface load | 45 m³/m²/h | 90 m³/m²/h | 117 m³/m²/h | 235 m³/m²/h | 250 m³/m²/h |

| Controller | Siemens Logo® | Siemens Logo® | Siemens Logo® | Siemens Logo® | Siemens Logo® |

Data are subject of technical changes.

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-NOISE-ELIMINATOR - With reduced noise level due to highly efficient sound insulation

- ASPUR-EASY-FILTERCHANGE - Simple, tool-free filter change

- ASPUR-Expansion-Extraction-System - Baffle plate, deflection and abrupt expansion of the intake process air, reduces the filter load and enables coarse particle separation

Device features