ASPUR aero3 mobile

Deduster ASPUR aero3 mobile

The mobile dust extractor from the aero3 mobile assembly is used in the manufacturing industry to extract and safely separate dust, chips and smoke.

In terms of filter technology and safety technology, the systems are designed so that they can be used indoors and the cleaned air can be returned to the work area. The device is also suitable for extracting laser and/or welding fumes that arise when welding or cutting alloy steels.

Drive

EC fans with different outputs offer a reliable drive and are infinitely adjustable from 0-100%. The exhaust air from the engine is soundproofed and is released slowly and quietly into the room.

Steering

A Siemens LOGO control built into the device enables manual or automatic adjustment to the desired performance parameters of the device. Using the Modbus equipment, all functions of the dust extractor can also be transferred to the customer's control system and operated there.

Filter cartridges

The horizontally installed filter cartridges can be service-friendly and easily replaced without tools. The cartridges are cleaned in the JETPULSE during operation either manually, time-controlled or via the differential pressure.

Suction system

The device can be equipped with one or two 360° rotating extraction arms or can optionally be connected to pipes (D200 mm) as a stationary device.

The suction system is designed in such a way that the sucked-in particles enter an expansion area and, at a slow rate of descent, enter the filter area with disposal containers underneath. This system reduces the strain on the filter and protects it from incoming sharp or glowing particles.

Disposal system

The integrated and utility model-protected disposal system consists of two pull-outs with a disposal container and PE bag as well as a deflection system, which enables the dust collection drawer to be removed very easily and without tools. To do this, pull the handle. The container lowers and is simultaneously pulled out to its entire depth. It can then be easily removed using two handles attached to the container. After changing the dust bag, the drawer is closed. The container is automatically moved up to its end position and seals there.

Exhaust air

The exhaust air flow is set diffusely by default. The blow-out is protected from splash water. The device is also prepared to be able to introduce the exhaust air outside or into the customer's ventilation or extraction systems.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| High-quality jetfilter system, installed horizontally |

| Simple, quick, tool-free filter change (servicefriendly) |

| Disposal system with dust drawer (utility model) |

| EC-blowers infinitely variable |

| Up to two 360° rotating extraction arms or with pipe available |

| Large, stable industrial castors with stoppers, large push handle |

| Exhaust air diffuse or with pipe |

Order now our dust extractor aero3 mobile for your workplace!

Optional device features |

|---|

| Filter class H |

| Cartridge filter ePTFE membrane |

| Stainless steel version |

| Dust-Ex Z22 |

| Activated carbon filter system |

| Simple device control (On, Off, Poti) |

| 360° Extraction arms |

Order now our dust extractor aero3 mobile for your workplace!

Areas of application |

|---|

| Processes |

| Lasering, welding, cutting |

| Filling, mixing |

| Packaging |

| Materials |

| Fume, smoke |

| Dust, fine particles |

| Fibers, fabrics |

Order now our dust extractor aero3 mobile for your workplace!

Technical data

| aero3 mobile EC1.4 | aero3 mobile EC2.8 | |

|---|---|---|

| Item no. | 9040008 | 9040009 |

| Drive | EC blower | EC blower |

| Air volume flow | max. 940 m³/h | max. 1880 m³/h |

| Negative pressure | max. 5000 PA | max. 5000 PA |

| Drive power | 1.4 kW | 2.8 kW |

| Voltage | 230 / 400 V | 230 / 400 V |

| Sound emission | 62 dB(A) | 63 db(A) |

| Weight | 238 kg | 240 kg |

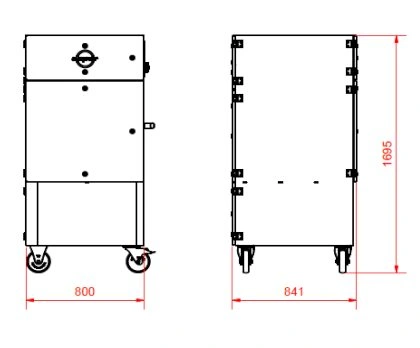

| Dimensions (l,w,h) | 870x840x1700 mm | 870x840x1700 mm |

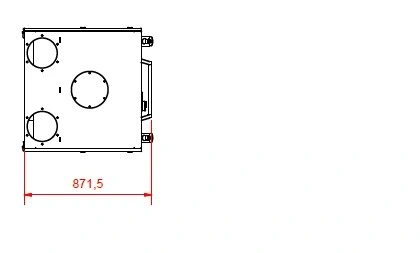

| Intake port (d) | 2x 125 mm (200 mm) | 2x 125 mm (200 mm) |

| Dust coll. container | 30 L | 30 L |

| PE-bag conductive | yes | yes | Powder coating | RAL9016 semi-gloss | RAL9016 semi-gloss | Cartridge filter | M | M |

| Filter surface | 16 m² | 16 m² |

| Filter surface load | 58 m³/m²/h | 117 m³/m²/h |

| Filter cleaning | JetPulse | JetPulse |

| Controller | Siemens Logo® | Siemens Logo® |

Optionals features

| aero3 mobile EC1.4 | aero3 mobile EC2.8 | |

|---|---|---|

| HEPA filter class H14 | yes | yes |

| Dust Ex-Zone 22 | yes | yes |

| ePTFE Cartridge filter | yes | yes |

| Activated carbon filter | yes | yes |

| Stainless steel version | yes | yes |

| 360° extraction arms | yes | yes |

| Manual control¹ | yes | yes |

Data are subject of technical changes.

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-DUAL-DOOR-System - Accessible from two sides via large doors

- ASPUR-NOISE-ELIMINATOR - With reduced noise level due to highly efficient sound insulation

- ASPUR-EASY-FILTERCHANGE - Simple, tool-free filter change

- ASPUR-Expansion-Extraction-System - Expansion of the sucked-in process air and redirection, reduces the incoming suction speed and enables coarse particle and spark separation

Device functions