ASPUR centravac

Extraction system ASPUR centravac

ASPUR extraction systems were designed for the extraction of organic and inorganic process dust, chips and dry or aqueous media.

The extraction systems are used in stationary versions in industrial companies in order to be able to extract from several suction points at the same time. The suction points in the building are connected by a network of pipes so that a uniform flow rate prevails. Depending on your wishes, one or more suction points can be open at the same time. The electrical connection to the extraction is made via cable or via radio when operating the individual extraction points. If desired, manually operated flaps or sliders can be installed.

ASPUR extraction systems can also be connected directly to processing machines and automatically alternately extract the resulting process materials. Additional accessories such as chip breakers etc. are usually necessary for this.

In terms of filters and safety, the systems are designed so that they can be used indoors and in potentially explosive areas. The systems can be equipped with explosion protection and/or fire protection systems.

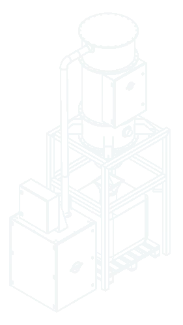

Drive

Side channel blowers with the latest generation of IE3 motors offer a low-noise and reliable, maintenance-free drive. Together with the integrated frequency converter, the motors can be adjusted manually or automatically to the desired performance. This equipment means that only the services that are actually necessary are used, which reduces power consumption. The drive unit has two large access doors that can be easily opened, allowing access to the interior of the engine area.

Controller

The built in Siemens LOGO control (or optionally S7) enables manual or automatic adjustment to the desired performance parameters of the device. Using the Modbus equipment, all functions of the extraction system can also be placed on a customer control system and operated there.

Filter

The filter unit is equipped with 4 cartridge filters and is cleaned by using the JetPulse principle with a compressed air tank installed inside on the clean gas side. A large access door with industrial hinges, which extends over the entire height and width of the filter module, allows the user quick and service-friendly access to the filter area.

The filters can be changed easily, quickly and service-friendly and without tools.

Extractionsystem

The filter unit can be installed on the frame so that the suction opening can be opened on 4 sides. The suction system takes place directly in the expansion area, which reduces the flow speed and the filter load and at the same time protects the filters from incoming particles.

Disposalsystem

Suctioned dust and chips are led into the suction funnel and discharged here via a rotary valve into a BigBag disposal system. Alternatively, other containers such as troughs or slide systems can also be used.

Assemblies

Thanks to the modular design, HEPA filters, activated carbon filters, explosion and fire protection systems as well as various discharge systems can be installed according to the customer's individual wishes and can also be retrofitted later.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| High-quality jet filter system, integrated into the device, resulting in lower noise emissions |

| Simple, quick, tool-free filter change (service-friendly) |

| Large filter access doors on one side (service-friendly) |

| Side channel blower with latest generation IE3 motors |

| Control cabinet with frequency converter, Modbus and display (user-friendly) |

Order our latest centravac extraction system for your company now!

Optional device features |

|---|

| Filter class H |

| HEPA H14 filter |

| ePTFE-membrane catridge filter |

| Activated carbon filter system |

| Stainless steel version |

| Dust-Ex Z22 and Z21 |

| Gas-Ex Z2 and Z1 |

| Different discharge systems |

| Fire and explosion protection equipment |

Order our latest centravac extraction system for your company now!

Areas of application |

|---|

| Processes |

| Lasering, welding, cutting |

| Drilling, lathing, milling |

| Filling, mixing |

| Packaging |

| Materials |

| Dust, fine particles |

| Chips |

| Fibers, fabrics |

Order our latest centravac extraction system for your company now!

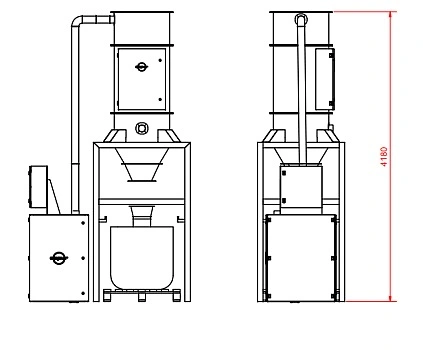

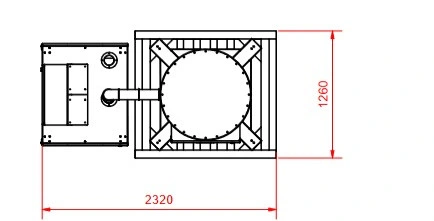

Technical data

| centravac D12,5 1100 M |

centravac D18,5 1120 M |

centravac D25 2000 M |

|

|---|---|---|---|

| Item no. | 9080001 | 9080002 | 9080003 |

| Air volume flow | max. 1100 m³/h | max. 1120 m³/h | max. 2000 m³/h |

| Negative pressure | max. 280 mbar | max. 350 mbar | max. 350 mbar |

| Drive power | 12.5 kW | 18,5 kW | 25,0 kW |

| Voltage | 400 V | 400 V | 400 V |

| Sound emission | 62 dB(A) | 64 db(A) | 64 dB(A) |

| Weigth | 1190 kg | 1200 kg | 1220 kg |

| Dimensions (l,w,h) | 2320x1260x4180 mm | 2320x1260x4180 mm | 2320x1260x4180 mm |

| Inport take (d) | 100 mm | 100 mm | 100 mm |

| Dust coll. container | BigBag | BigBag | BigBag |

| Powder coating | RAL9016 semi-gloss | RAL9016 semi-gloss | RAL9016 semi-gloss |

| Cartridgefilter¹ | M | M | M |

| Filter surface | 20 m² | 20 m² | 20 m² |

| Filter surface load | 56 m³/m²/h | 56 m³/m²/h | 100 m³/m²/h |

| Filter cleaning | JetPulse | JetPulse | JetPulse |

| Controller² | Siemens Logo® | Siemens Logo® | Siemens Logo® |

Optional features

| centravac D12,5 1100 M |

centravac D18,5 1120 M |

centravac D25 2000 M |

|

|---|---|---|---|

| HEPA H14 filter | ja | ja | ja |

| Dust Ex-Zone 22/21 | ja | ja | ja |

| Gas Ex-Zone 2/1 | ja | ja | ja |

| Explosion prevention* | ja | ja | ja |

| Fire prevention* | ja | ja | ja |

| ePTFE cartridge filter | ja | ja | ja |

| Activated carbon filter | ja | ja | ja |

| Stainless steel version | ja | ja | ja |

| Hobbock container | ja | ja | ja |

| Container with PE bag | ja | ja | ja |

| Double slider | ja | ja | ja |

Data are subject of technical changes.

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-MODULAR-DESIGN - Structure in modular assemblies, enables a wide range of variants

- ASPUR-NOISE-ELIMINATOR - With reduced noise levels thanks to highly efficient sound insulation

- ASPUR-SAFETY-FILTERCHANGE - Simple, tool-free filter change

- ASPUR EXPANSIONS-EXTRACTION-SYSTEM - Expansion of the sucked-in process air and redirection, reduces the incoming suction speed and enables coarse particle and spark separation

Device features