ASPUR ivac endless bag

Industrial vacuum cleaner ASPUR ivac endless bag

Industrial vacuum cleaner, designed for the extraction of dry substances and dust in pharmaceutical and industrial environments and directly on processing machines.

Assemblies

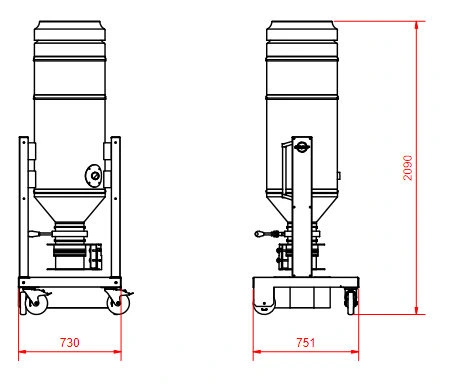

The chassis of the industrial vacuum cleaner made of 3 mm sheet steel is very stable and offers a comfortable and high-quality unit with the stainless steel round containers. The chassis can also be supplied in brushed 3 mm stainless steel as an option.

High-quality wheels and swivel castors with stoppers in antistatic design make the appliance very easy to manoeuvre. Large push handles allow easy manoeuvring.

Drive

The industrial vacuum cleaners are equipped with powerful side channel blowers or EC motors, which are infinitely variable. All motors can be used in continuous operation. The sound insulation bonnet protects the fan from external influences, is easy to clean and reduces noise emissions. In addition, the devices are designed to be fitted with an additional HEPA-H14 filter element after the motor. The appliance can also be docked onto the customer's exhaust air pipework as standard. All round containers are made of brushed stainless steel and are suitable for use in pharmaceutical or food areas, but also in many other production plants such as in mechanical engineering, the automotive industry and others.

Control unit

The industrial suction unit can be wired to Harting and is equipped with a main switch as standard and a potentiometer for EC blowers for infinitely variable adjustment of the air requirement. Alternatively, we use a Siemens LOGO or S7 controller with display and a Modbus link. These enable manual or automatic adjustment of the device's performance parameters or control by the master processing machines.

Using the Modbus equipment, all functions of the extraction system can also be transferred to a control system provided by the customer, from where they can be read and operated.

Filter

The star filter filter class "M" is cleaned with an integrated electric unbalance motor, which is installed on the clean gas side. This filter reliably filters out fine dust and coarse particles.

The appliance can optionally be fitted with one or two additional HEPA fine dust filters. Optionally, 2 HEPA H14 filters or 1 HEPA filter can be used together with an activated carbon filter element. The 2nd filter is installed after the motor. The filtered exhaust air exits diffusely at the top of the appliance around the circumference, but can also be connected directly to the customer's exhaust air system in a few simple steps.

Extraction system

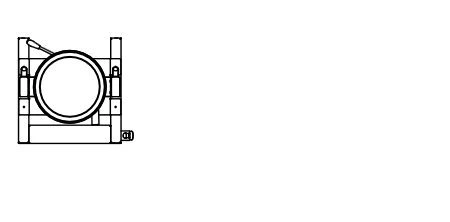

The suction takes place tangentially at the filter container and is channelled downwards to the hopper through an internal funnel using the centrifugal principle. This achieves better process dust separation. At the same time, this system protects the filter from any sharp objects or chips that may be sucked in.

Disposal system

After switching off the fan, the vibrator is started manually or automatically and causes the pocket filter to vibrate so that adhering fine dust falls into the hopper. After the flap is opened, the process dust enters the endless bag below. A PA ring with a round cord and clamping ring secures the endless bag to prevent dust from escaping.

The dust-free disposal system is used for problematic, e.g. carcinogenic substances, to provide maximum protection for workers.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| Brushed stainless steel container |

| Chassis powder-coated RAL9016 semi-gloss |

| Endless bag system for dust-free disposal |

| Large push handles |

| Industrial castors with stopper and wheels D160, conductive |

| High-quality star filter M with electric filter cleaning |

| Various powerful EC blowers, continuous operation |

| Encapsulated motors with sound insulation |

| Small control (on/off switch, vibrator, potentiometer for EC) |

Order our industrial vacuum cleaner for your working areas!

Optional device features |

|---|

| JetPulse filter system with pneumatic filter cleaning |

| 1st HEPA filter H14 |

| 2nd HEPA filter H14 |

| Activated carbon filter |

| Stainless steel chassis |

| Siemens LOGO / S7 controller with display |

Order our industrial vacuum cleaner for your working areas!

Areas of application |

|---|

| Processes |

| Filling, mixing |

| Packaging |

| Materials |

| Dust, fine particles |

| Fibers, fabrics |

Bestellen Sie jetzt unseren neuesten Industriesauger IVAC EB für ihr Unternehmen!

Technical data

| ivac EC1.1 350 TF M EB |

ivac EC2.2 700 TF M EB |

ivac EC1.4 940 TF M EB |

|

|---|---|---|---|

| Item no. | 9090020 | 9090021 | 9090022 |

| Air volume flow | max. 350 m³/h | max. 700 m³/h | max. 940 m³/h |

| Negative pressure | max. 100 mbar | max. 100 mbar | max. 50 mbar |

| Drive power | 1.1 kW | 2x 1.1 kW | 1.4 kW |

| Voltage | 230 / 400 V | 230 / 400 V | 230 / 400 V |

| Sound emission | 62 dB(A) | 64 db(A) | 64 dB(A) |

| Weight | 130 kg | 135 kg | 132 kg |

| Dimensions (l,w,h) | 730x750x2088 mm | 730x750x2088 mm | 730x750x2088 mm |

| Dimensions¹ (l,w,h) | 730x750x2288 mm | 730x750x2288 mm | 730x750x2288 mm |

| Inport take (d) | 50 / 70 mm | 50 / 70 mm | 50 / 70 mm |

| Dust coll. container | Endless bag | Endless bag | Endless bag |

| Powder coating | RAL9016 semi-gloss | RAL9016 semi-gloss | RAL9016 semi-gloss |

| Mainfilter typ M | Star filter | Star filter | Star filter |

| Filter surface | 6 m² | 6 m² | 6 m² |

| Filter surface load | 58 m³/m²/h | 116 m³/m²/h | 156 m³/m²/h |

| Filter cleaning | Electric vibrator | Electric vibrator | Electric vibrator |

| Controller | On/Off, vibrator, poti | On/Off, vibrator, poti | On/Off, vibrator, poti |

Optionale Ausstattungen

| ivac EC1.1 350 TF M EB |

ivac EC2.2 700 TF M EB |

ivac EC1.4 940 TF M EB |

|

|---|---|---|---|

| 1st HEPA H14 filter | yes | yes | yes |

| 2nd HEPA H14 filter | yes | yes | yes |

| Jetfilter system¹ | yes | yes | yes |

| Activated carbon filter | yes | yes | yes |

| Stainless steel chassis | yes | yes | yes |

| Siemens LOGO/S7² | yes | yes | yes |

Data are subject of technical changes.

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-MODULAR-DESIGN - Design in modular assemblies, enables extensive range of variants

- ASPUR-NOISE-ELIMINATOR - With reduced noise level thanks to highly efficient sound insulation

- Stainless steel flap with Tri-Clamp connection

- GMP-Version

- Dust-free process dust disposal

Gerätefunktionen