ASPUR aero2HD

High-pressure deduster ASPUR aero2HD

The aero2HD high-pressure deduster safely extracts dust, smoke, chips and gases* from processing machines and processes and collects them either in a container, hobbock, dust bag or endless bag system. The very sturdy housing is made of 3mm steel or stainless steel sheet and can be supplied in almost any RAL color. Standard is powder coating RAL 9016.

*) only with activated carbon filter

The units are equipped with the latest filters, which can be changed without tools. Large access doors installed on both sides, which extend over the entire height and width of the modules, allow the user quick and service-friendly access to all components.

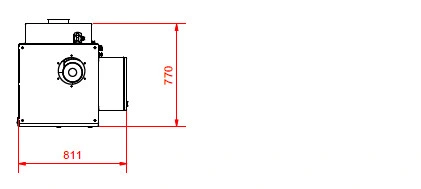

Drive

The drive is provided by EC high-performance blowers and side channel blowers with IE3 motors of the latest generation. All variants can be used in multi-shift operation. The required air volume flow can be adjusted manually or optionally automatically by the integrated frequency converter (FU). Due to the high vacuum, these units can be used similar to a stationary industrial vacuum cleaner with very small suction cross sections.

Control system

A Rittal control cabinet with Siemens LOGO® modules and display as well as integrated frequency converter from Siemens (or identical in construction) allows manual or automatic adjustment to the desired performance parameters of the unit. This reduces unnecessary wear and tear. The integrated differential pressure sensor enables constant monitoring of the filter conditions. Via the Modbus equipment, all functions of the deduster can also be transferred to a customer's control system and operated from there.

Filter cartridge

The main filter cartridges are cleaned using the jet filter principle. The aluminum compressed air tank mounted above is automatically regulated by the control system according to time and/or differential pressure. All filters are easy to service and can be replaced without tools. Thanks to the modular design, HEPA filters, activated carbon filters and other filter systems can be added according to the customer's individual requirements and, under certain circumstances, retrofitted at a later date.

Dust container

The standard unit includes a round, lowerable and extendable collection container made of stainless steel with a push handle and conductive, steerable industrial castors. Optionally, a tinplate disposal container or a bag can be inserted. Alternatively, the unit is also available with a flap and endless bag for dust-free process dust disposal.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| High quality filtersystem |

| Integrated H14 filter (optional) |

| Simple, fast, tool-free filter change (replacable pre-filter) |

| Large access doors (service friendly) |

| Drives: EC high performance blower with side channel blower |

| Control cabinet with frequency converter and display (user-friendly) |

| Incl. Modbus TCP control and 24V potential-free contact |

Order now our dust extractor aero2eco for your workplace!

Optional device features |

|---|

| Gas-Ex Z2 and Z1 |

| Dust-Ex Z22 and Z21 |

| UL, CCC, GMP-compliant design |

| Stainless steel version |

| All RAL colors in powder coating |

| Activated carbon filter system |

| Fire protection equipment |

| Explosion protection equipment |

| HEPA H14 filter |

| Endless bag with flap |

| Precoating system for sticky process dust |

Order now our dust extractor aero2eco for your workplace!

Areas of application |

|---|

| Processes |

| Lasering, welding, cutting |

| Filling, mixing |

| Packaging |

| Materials |

| Fume, smoke |

| Dust, fine particles |

Order now our dust extractor aero2eco for your workplace!

Technical data

| aero2HD D3 | aero2HD D4 | |

|---|---|---|

| Item no. | 9050002 | 9050003 |

| Drive | Side channel blower | Side channel blower |

| Air volume flow | max. 300 m³/h | max. 450 m³/h |

| Negative pressure | max. 310 PA | max. 250 PA |

| Drive power | 3.0 kW | 4.0 kW |

| Voltage | 400 V | 400 V |

| Sound emission | 63 dB(A) | 64 db(A) |

| Weigth | 250 kg | 260 kg |

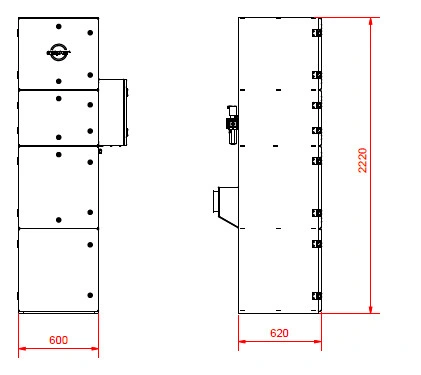

| Dimensions (l,w,h) | 600x600x2200 mm | 600x600x2200 mm |

| Dimensions¹ (l,w,h) | 800x800x2200 mm | 800x800x2200 mm |

| Intake port (d) | 150 mm | 150 mm |

| Dust coll. container² | 50 L | 50 L | Powder coating | RAL9016 mat | RAL9016 mat | Main filter typ M | 4x Cartridge filter | 4x Cartridge filter |

| Filter surface | 24 m² | 24 m² |

| Filter surface load | 12 m³/m²/h | 19 m³/m²/h |

| Controller | Siemens Logo® | Siemens Logo® |

Right trimmed columns can be scrolled (wiped) to the left!

Optional features

| aero2HD D3 | aero2HD D4 | |

|---|---|---|

| HEPA filter class H14 | yes | yes |

| Dust Ex-Zone 22 | yes | yes |

| Dust Ex-Zone 21 | yes | yes |

| Gas Ex-Zone 2 | yes | yes |

| Gas Ex-Zone 1 | yes | yes |

| Explosion prevention* | yes | yes |

| Fire prevention* | yes | yes |

| Activated carbon filter | yes | yes |

| Stainless steel version | yes | yes |

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-NOISE-ELIMINATOR - With reduced noise level due to highly efficient sound insulation

- ASPUR-EASY-FILTERCHANGE - Simple, tool-free filter change

- ASPUR-Expansion-Extraction-System - Baffle plate, deflection and abrupt expansion of the intake process air, reduces the filter load and enables coarse particle separation

Device features