ASPUR aerog4

Oil mist separator ASPUR aerog4

Oil mist separators of the aerog4 assembly are used in the manufacturing industry to extract and safely separate oil mist, emulsion mist, aqueous solutions, fumes and gases* with proportionate solids. The installation of the units indoors and the recirculation of the cleaned air comply with the current TRGS guidelines.

*) only with activated carbon filter

The plants are equipped with Siemens IE3 motors of the latest generation. Together with the installed frequency converter, the motors can be variably adjusted to the desired outputs. Due to this equipment, only the actually necessary power is called up, which reduces power consumption and wear.

Large access doors installed on both sides, which extend over the entire height and width of the modules, allow the user quick and service-friendly access to all components. In addition, all filter systems are designed to be changed without tools.

The high-quality filter system with integrated HEPA H13 filter, stands for a long operating time with simultaneous best separation results.

Due to the modular design, HEPA filters, activated carbon filters, explosion and fire protection systems as well as various discharge systems can be added according to the customer's individual requirements and, under certain circumstances, upgraded at a later date.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| High-quality, multi-stage filter system |

| Integrated H13 filter |

| Simple, fast and tool-free filter changing |

| Coarse filter replaceable |

| Large access doors on both sides (service-friendly) |

| IE3 centrifugal fan of the latest generation |

| Control cabinet with frequency inverter and display (user-friendly) |

Order our oil mist seperator aerog1 for your workplaces!

Optional device features |

|---|

| Gas-Ex Z2 and Z1 |

| Pump for recirculation of the separated liquids |

| Completely available in stainless steel design |

| All RAL colors in powder coating in powder coating |

| Activated carbon filtersystem |

| Explosion and fire protection equipment |

Order our oil mist seperator aerog1 for your workplaces!

Areas of application |

|---|

| Processes |

| Lasering, welding, cutting |

| Materials |

| Aerosole, vapors |

| Fume, smoke |

Order now our storage filter airsorb2 for your workplaces!

Technical data

| aerog4 D3 |

aerog4 D5.5 |

aerog4 D11 |

|

|---|---|---|---|

| Item no. | 9030004 | 9030003 | 9030001 |

| Air volume flow | max. 4300 m³/h | max. 6500 m³/h | max. 9000 m³/h |

| Negative pressure | max. 3500 PA | max. 4500 PA | max. 6000 PA |

| Drive power | 3.0 kW | 5.5 kW | 11 kW |

| Voltage | 400 V | 400 V | 400 V |

| Sound emission | 60 dB(A) | 63 db(A) | 65 dB(A) |

| Weight | 620 kg | 690 kg | 780 kg |

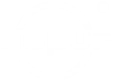

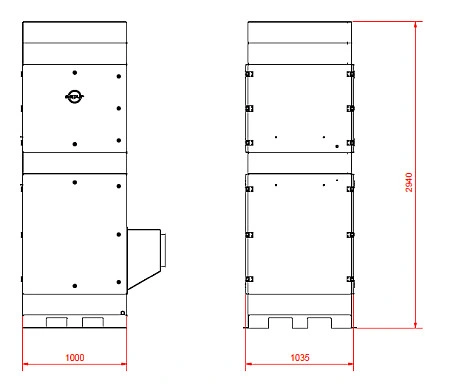

| Dimensions (l,w,h) | 1000x1000x3100 mm | 1000x1000x3100 mm | 1000x1000x3100 mm |

| Dimensions¹ (l,w,h) | 1000x1600x3100 mm | 1000x1600x3100 mm | 1000x1600x3100 mm |

| Intake port (d) | 300 mm | 300 mm | 300 mm |

| Dust coll. container² | 200 L | 200 L | 200 L |

| Powder coating | RAL9016 mat | RAL9016 mat | RAL9016 mat |

| Filter class | H13 | H13 | H13 |

| Filter surface | 80 m² | 80 m² | 80 m² |

| Filter surface load | 54 m³/m²/h | 81 m³/m²/h | 112 m³/m²/h |

| Controller³ | Siemens Logo® | Siemens Logo® | Siemens Logo® |

Right trimmed columns can be scrolled (wiped) to the left!

Optional features

| aerog4 D3 |

aerog4 D5.5 |

aerog4 D11 |

|

|---|---|---|---|

| HEPA H14 filter | yes | yes | yes |

| Gas Ex-Zone 2 | yes | yes | yes |

| Gas Ex-Zone 1 | yes | yes | yes |

| Explosion prevention* | yes | yes | yes |

| Fire prevention* | yes | yes | yes |

| Activated carbon filter | yes | yes | yes |

| Stainless steel version | yes | yes | yes |

Data are subject of technical changes.

Right trimmed columns can be scrolled (wiped) to the left!

Special features

- ASPUR-MODULAR-DESIGN - Structure in modular assemblies, enables extensive variety of variants

- ASPUR-DOOR-SYSTEM - Large doors for barrier-free access

- ASPUR-NOISE-ELIMINATOR - With reduced noise level due to motor sound insulation

- ASPUR-SAFETY-FILTERCHANGE - Simple, tool-free filter change

- ASPUR EXPANSIONS-ANSAUGSYSTEM - Baffle plate, deflection and abrupt expansion of the intake process air, reduces the filter load and enables coarse particle separation

Device features