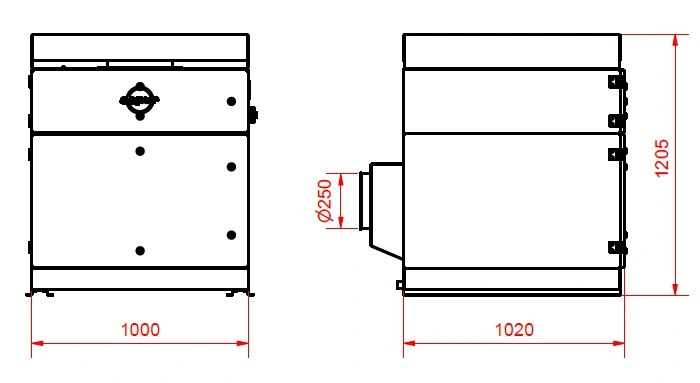

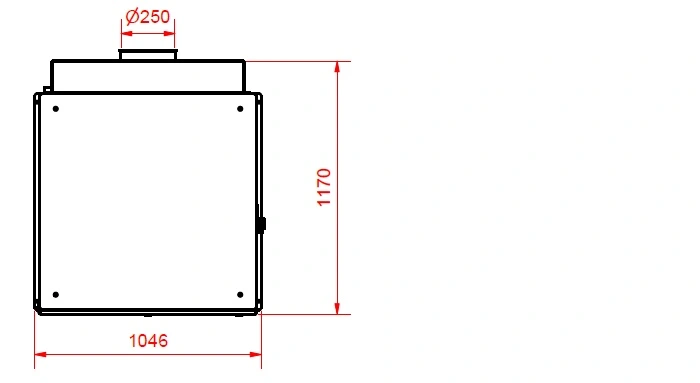

ASPUR sopra4 attachment device

Oil mist separator sopra4 attachment device

Aerosol separators of the sopra assembly are used in the manufacturing industry to extract and safely separate oil mist, emulsion mist, aqueous solutions, fumes and gases* with proportionate solids precisely at the point of origin. The attachment units are installed on machining centers, milling machines or lathes. The recirculation of the cleaned air complies with the current TRGS guidelines.

*) only with activated carbon filter

The units are equipped with EC high-performance blowers of the latest generation and are controlled continuously from 0-100%, so that the desired performance parameters can be set variably. This allows the operator to adjust the consumption to an optimum. In addition, the blowers are designed to be able to call up sufficient power even with a high raw gas input and correspondingly high filter load.

Large access doors, which extend over the entire height and width of the modules, allow the user quick and service-friendly access to all components. In addition, all filter systems are designed so that they can be changed without tools.

The high-quality filter system with integrated HEPA H13 filter, stands for a long operating time with simultaneous best separation results. The intake system developed by ASPUR with baffle plate, simultaneous abrupt deflection and expansion enables pre-separation of the particles with simultaneous filter protection by coarse and sharp-edged particles.

Due to the modular design, HEPA filters, activated carbon filters, explosion and fire protection systems as well as various discharge systems can be added according to the customer's individual requirements and, under certain circumstances, retrofitted at a later date.

Standard equipment

Optional equipment

Product data

Product features |

|---|

| High-quality, multi-stage filter system |

| Integrated H13 filter |

| EC Blower 230V / 400V selectable |

| Easy, fast, tool-free filter change in 1min! |

| Drive with EC high power blower |

| Large access door on one side (service-friendly) |

| Siemens LOGO control or Harting plug selectable |

Order our oil mist seperator sopra1 attachment dev for your milling machines!

Optional device features |

|---|

| Pump for recirculation of the separated liquids |

| Completely available in stainless steel design |

| All RAL colors in powder coating |

| Activated carbon filtersystem |

| Explosion and fire protection equipment |

| Control cabinet with frequency converter and display (user-friendly) |

Order our oil mist seperator sopra1 attachment dev for your milling machines!

Areas of application |

|---|

| Processes |

| Lasering, welding, cutting |

| Materials |

| Aerosole, vapors |

| Fume, smoke |

Order now our storage filter sopra1 attachment dev for your milling machines!

Technical data

| sopra4 EC 4.2 3000 | sopra4 EC 5.6 4000 | |

|---|---|---|

| Item no. | ||

| Drive | EC high-pressure blower | EC high-pressure blower |

| Air volume flow | max. 2820 m³/h | max. 3760 m³/h |

| Negative pressure | max. 5000 PA | max. 5000 PA |

| Drive power | 3x 1.4 kW | 4x 1.4 kW |

| Voltage² | 230 V / 400 V | 230 V / 400 V |

| Sound emission | 63 dB(A) | 63 dB(A) |

| Power consumption | 6.1 A | 6.1 A |

| Weigth | 180 kg | 190 kg |

| Dimensions (l,w,h) | 500x520x1145 mm | 500x520x1145 mm |

| Dimensions¹ (l,w,h) | 700x700x1145 mm | 700x700x1145 mm |

| Intake port (d) | 100/125/150 mm | 100/125/150 mm |

| Dust coll. container | 25 L | 25 L |

| Powder coating | RAL9016 mat | RAL9016 mat |

| Main filter multi-level | Cartridge filter | Cartrigde filter |

| Filter surface | 8 m² | 8 m² |

| Filter surface load | 117 m³/m²/h | 117 m³/m²/h |

| Controller³ | Siemens Logo® | Siemens Logo® |

²) 230V or 400V optionally

³) Siemens Logo with Modbus TCP or Harting plug optionally

Optional equipment

| sopra4 EC 4.2 3000 | sopra4 EC 5.6 4000 | |

|---|---|---|

| HEPA H14 filter | yes | yes |

| Dust Ex-Zone 22 | yes | yes |

| Dust Ex-Zone 21 | no | no |

| Gas Ex-Zone 2 | yes | yes |

| Gas Ex-Zone 1 | on request | on request |

| Explosion prevention* | on request | on request |

| Fire prevention* | on request | on request |

| Activated carbon filter | yes | yes |

| Stainless steel version | yes | yes |

All data are subject of technical changes.

Special features

- ASPUR-MODULAR-DESIGN - Structure in modular assemblies, enables extensive variety of variants

- ASPUR-DOOR-SYSTEM - Large doors for barrier-free access

- ASPUR-NOISE-ELIMINATOR - With reduced noise level due to motor sound insulation

- ASPUR-SAFETY-FILTERCHANGE - Simple, low contamination, tool-free filter change

- ASPUR EXPANSIONS-ANSAUGSYSTEM - Baffle plate, deflection and abrupt expansion of the intake process air, reduces the filter load and enables coarse particle separation

Device features